September 2005

by Peter Scott

The UZZ32 Active Soarer is the only Soarer with piston accumulators in the

suspension to store energy. Fluids are practically incompressible and cannot

therefore store pressure energy. The compressibility of a gas (nitrogen) is

utilized in hydro-pneumatic accumulators for storing fluids. Piston accumulators

are designed on this principle, using nitrogen as the compressible medium.

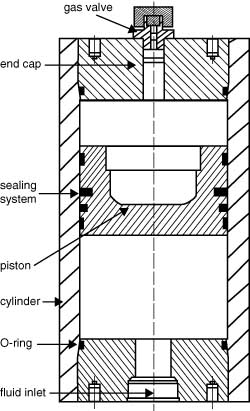

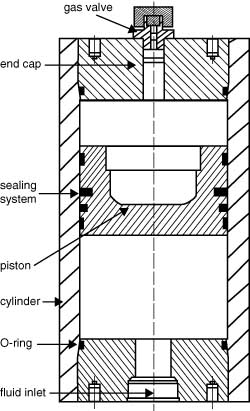

The piston accumulator consists of a fluid section and a gas section, with the

piston acting as a gas-proof screen. The gas section is precharged with dry

nitrogen gas. The fluid section is connected to the hydraulic circuit so that

the piston accumulator draws in fluid when the pressure increases thus

compressing the gas. When the pressure drops, the compressed gas expands and

forces the stored fluid into the circuit.

The pressure fluctuations occurring in hydraulic systems can be periodic or

single occurrence problems due to:

• Flow rate fluctuations from displacement pumps

• Actuation of shut-off and control valves with short opening and closing times

• Switching pumps on and off

• Sudden linking of hydraulic circuits with different pressure levels

On the Active Soarer this is manifested in three main ways:

- Sudden movements in suspension level while at a stoplight.

- The dreaded bouncing, where the suspension continues to oscillate for no

good reason

- High speed fast "patter" bouncing.

My car gets all three types of bounce. The first two are very mild on my car.

The third type is very scary at speed on a circuit. Below is a short video

(450kB) of me driving Ken around a bend. The bounce starts, Ken exclaims

surprise and Rex the dog barks in the back.

The passenger is clearly bouncing with the suspension.

All of my bounce problems went away when I had the struts recharged with

nitrogen:

http://planetsoarer.com/nitrogen/nitrogen.htm

After a few months the symptoms started to return indicating that the

nitrogen was slowing ebbing away again. At the last circuit sprint I attended at

Phillip Island the high speed bounce while cornering had returned. Turning into

a right hand sweeper at 200 km/hr (125 mph) with the car bouncing 5 times a

second is no good at all!

So rather than just re-gas the accumulator again - I wanted to fix the leak

first. The accumulator is a tube with welded end caps. To get at the internal

piston and seal inside the weld would have to be removed and the end cap taken

off. It all had to be done carefully so the end cap could be replaced and welded

again.

I used a oil drip tray to work on the strut- keeps it clean. I had to grind

the end of a 36 mm spanner to make it thin enough to unscrew the accumulator

from the top part of the strut. When I removed the gas valve no gas came out -

it was completely empty. A small amount of hydraulic fluid came out the hole - a

sure sign of a failed seal.

The accumulator was then placed in a lathe and the weld professionally

machined until the join line of the end cap was visible. Then the end cap could

be tapped off with a hammer. I used an old rubber bush on the air blower to push

the piston out of the bore of the accumulator.

The end cap removed from the accumulator.

The bore is in good shape - the marks are oily rag wipe marks only.

The piston runs on bronze guide rings with an o-ring in the middle. The

bronze guides looked to be in excellent condition.

The o-ring is looking a bit sorry. I'll replace this o-ring and get the

accumulator welded up.

I want to look at replacing the gas filler screw with a banjo fitting

perhaps. This 6mm eye fitting, banjo bolt and copper washers retailed for $14

Aud from a fuel injection shop. Very rare to get one this small. There are

clearance issues with the front struts - I am unsure how things will pan out at

the moment.

Schrader valves like the one above are available for $21 Aud for a pack of

six from professional commercial air-conditioning suppliers.

So now I will cut open the remaining accumulators, reseal them with new

o-rings and then fit the schrader valves for easy convenient re-gassing.